- Home

- /

- News

- /

- Industry News

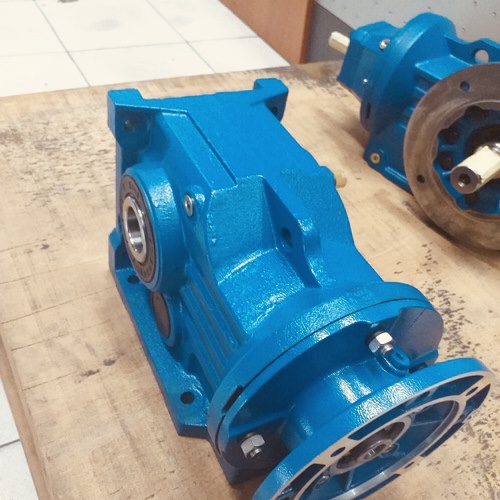

Helical Gearbox: Understand It’s Advantages And Applications

What are gears and gearboxes? A gear is a rotating machine part featuring cut teeth or cogs, which is supposed to mesh with another toothed part in order to transmit torque.

In a layman’s language, gears are one of the most crucial parts of any motors and machine which help to increase the torque output by providing gear reduction and adjusting the direction of rotation. Two or more gears working together in tandem are called transmission or gearbox. Geared devices are more likely to change the speed, torque, direction of a power source.

Types Of Gears And How Are They Different From Each Other?

Spur Gears

Spur gears are the most common products used in a series for large gear reduction. The teeth of spur gears are straight and are mounted in parallel on different shafts.

It’s advantages:

They offer constant velocity ratio

They are highly reliable

They are simple and easy in terms of making/ manufacturing

They are mostly used to transmit large amount of power

Helical Gears

Unlike Spur gears, Helical gears and Helical Gearbox both have the capacity to conduct a smooth operation. The teeth on a helical gear cut at an angle to the face of the gear. So, during the process when two of the teeth start to engage, the contact is gradual- starting at one end of the tooth and maintaining contact as the gear rotates into full engagement. When it comes to transmissions, helical is the most commonly used gears and it even generates large amounts of thrust.

It’s Advantages:

The angled teeth engage more gradually than do spur gear teeth so that they can run more smoothly.

Helical gears, as well as helical gearboxes, are highly durable and ideal for high load applications.

It has the capacity to transmit motion and power between either parallel or right angle shafts.

Bevel Gear

Bevel gears are mostly used to change the direction of shaft’s rotation. They have teeth in straight, spiral, hypoid shapes. Each one of a kind, for example, straight teeth have similar characteristics to spur gears while spiral operates the same as helical gears as they produce less vibration.

It’s Advantages:

Bevel are such kind of gears that makes it possible to change the operating angle.

The variety of teeth on each wheel allows mechanical advantage to be changed.

Worm gears

Most of the Industrial Gearbox Suppliers prefer providing Worm Gears to their valuable clients as it is used for large gear reductions. The setup is designed in such a way that setup can turn the gear, but the gear cannot turn the worm. The angle of the worm is shallow and as a result, the gear is used in conveyor systems for brake or emergency stop.

Its Advantages

Worm Gears operate more silently and smoothly

They are self-locking

They occupy less amount of space

They have good meshing effectiveness and thus, can be used to reduce speed and increase torque.

Why Helical Gears?

Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix which makes it transmit power between parallel or right angle axes. The main difference between a helical gearbox and others is that the teeth form a helix and has the potential to run more quietly. Another advantage of using these gears are that they will have more capability to transmit load between two parallel shafts as compared to the similar module and equivalent width of spur gears. And of course, there will be less wear and tear as the load will be distributed between several teeth.

Its Application

Most of the reputable Industrial Gearbox Suppliers suggest helical gears to work under heavy load efficiency and of course when we need silent operation such as automotive applications.

Fertilizer industries, printing industries, and earth-moving industries

Steel, rolling mills, power and port industries

Textile industries, plastic industries, food industries, conveyors, elevators, blowers, compressors, oil industries & cutters.

Addition to the above applications, there are many others. The overall application of helical gears and helical gearboxes are widespread. Keep an eye on the space to know more.

Key: Horizontal Inverter duty, Vertical Inverter Duty motor, DC Brake motor Oil Pressure Motor, Small Gear motor-Horizontal Type Ac Gear Motor, Small Gear motor-Vertical Type Ac Gear Motor, Helical Gears High Gear Ratio, Vertical Gear box High Gear Ratio, Horizontal double shaft motor, Vertical double shaft motor, Horizontal Flanged Gear reducer, CNC machine, AC mini Induction DC gear motor, Vertical Flanged Gear reducer, Horizontal Type Light load Gear motor, Vertical Type Light Load Gear motor, Horizontal Type Large Dc Motor, Horizontal Flanged Large Geared motor, Vertical Type Large Dc motor, Worm Gear Reducer, NMRV/NRV Worm Gear reducer, Horizontal reduction gear for electric motor, Vertical Cast iron Induction Motor, Horizontal 3 Phase ac induction motors, High Purity aluminium foil sheet Hairdressing Foil High Quality A, High Durability 3 phase ac induction motor, High Speed light weight ac induction motor, rotating machine, gearboxes

Newer articles

- Difference between AC motor and DC motor (16/06/2018)

- Some power pulse width modulation drivers for DC electric motors (16/06/2018)

- What Is Gear Manufacturing (19/06/2018)

- What is a worm gear motor (19/06/2018)

- Different Usages Of Gearboxes In Different Industries (30/05/2018)

- Pros and Cons of Helical Gearboxes (30/05/2018)

- Advantages and disadvantages of different types of gears (01/09/2018)

- How to Select a Gearmotors (01/10/2019)

- Pros & Cons of Worm Gear and Bevel Gear (30/05/2018)

- What are Brushless DC Motors (31/05/2019)

Older articles

- What is Motor Control Gear? (26/05/2018)

- What are Gear Motors Used For? (08/05/2018)

- Instructions for Gear Reducer Motor (02/05/2018)

- Gearbox Motors vs Integrated Gearmotors (16/04/2008)

- Hydraulic vs. Electromechanical Actuators (21/04/2018)

- AC or DC? brushed DC or brushless DC Gear Motor? (24/04/2008)

- Electric motors (21/04/2018)

- Fundamentals of Electric Motor Drives (05/04/2018)

- Permissible horsepower loading (05/04/2018)

- Worm Gear Speed Reducers (27/03/2018)

Join